AG.4X Series

The AG.4X is the #1 choice of Agricultural dealerships servicing tractors 20-900 Horsepower.

The all NEW AG.4X features the high tech 2100sXT DynoPro Computer System with Electronic Touch Screen Control, Temperature Watchdog Relay, and Emergency Water Flow shut down protection. In addition, a newly designed load unit provides high speed capability to dyno test engines, combines, forage harvesters, and irrigational power units.

***No maintenance on the internal load unit for the first 10 YEARS !!! This eliminates onsite service calls and saves the dealerships $500-$750 annually.

FEATURES

2100SXT DynoPro Computer

2100SXT DynoPro Computer

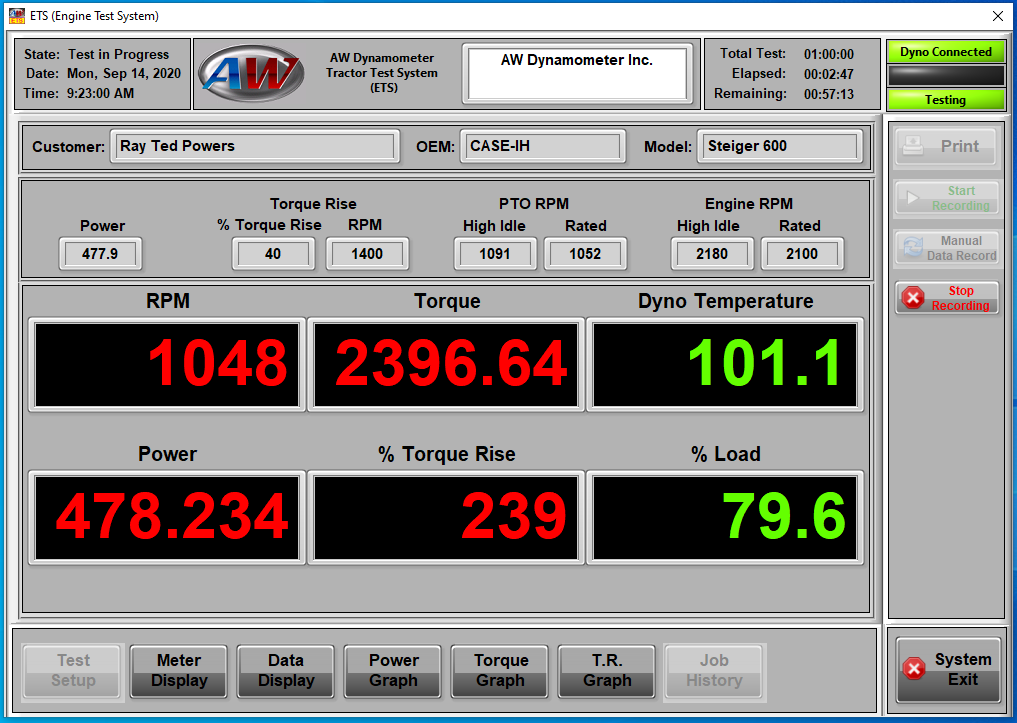

The 2100sXT DynoPro is AW’s NEW data and acquisition control system that contains a real-time dedicated high-speed processor. The 2100sXT screen displays Power, Torque, Torque Rise, Rpm, % Load Control availability, Dyno Temperature, and a precise Rpm generated hour meter. It’s Touch Screen Control allows the operator to apply or decrease the dyno load to the tractor by the use of pressing the up and down arrow keys. AW’s 2100sXT also features an Emergency E-Stop button to provide maximum safety at any time. Another unique feature of the 2100sXT is its Management Control Software. This software design allows the dealerships to view exceeded pre-set factory threshold limitations on the dyno and control the preventative maintenance of the X.Series Dynamometers. In order to capture real-time data to send to the dealerships OEM for warranty claims, or just simply save a dyno test for future customer reference, the 2100sXT allows the end-user to connect their laptop with AW’s ETS Software via USB connection located on the front face of the computer. Another advanced option is the ability to control the X.Series Dynamometer from the cab of the tractor by using ETS-XT which is an upgrade from the standard ETS.

Electronic Control

AW Electronic Control Via Touchscreen

In 2017, AW’s PTO Dynamometers were equipped with the NEW E-Valve Technology. This advanced technology allows the operators to use the Touch Screen on the 2100sXT to apply or decrease load to the tractor by the use of pressing the up and down arrow keys. The control and transition of pressure to the internal brake via electronic control is consistent and dynamic. AW’s 2100sXT also features an Emergency E-Stop to provide maximum safety at any moment.

ETS Software

ETS Software

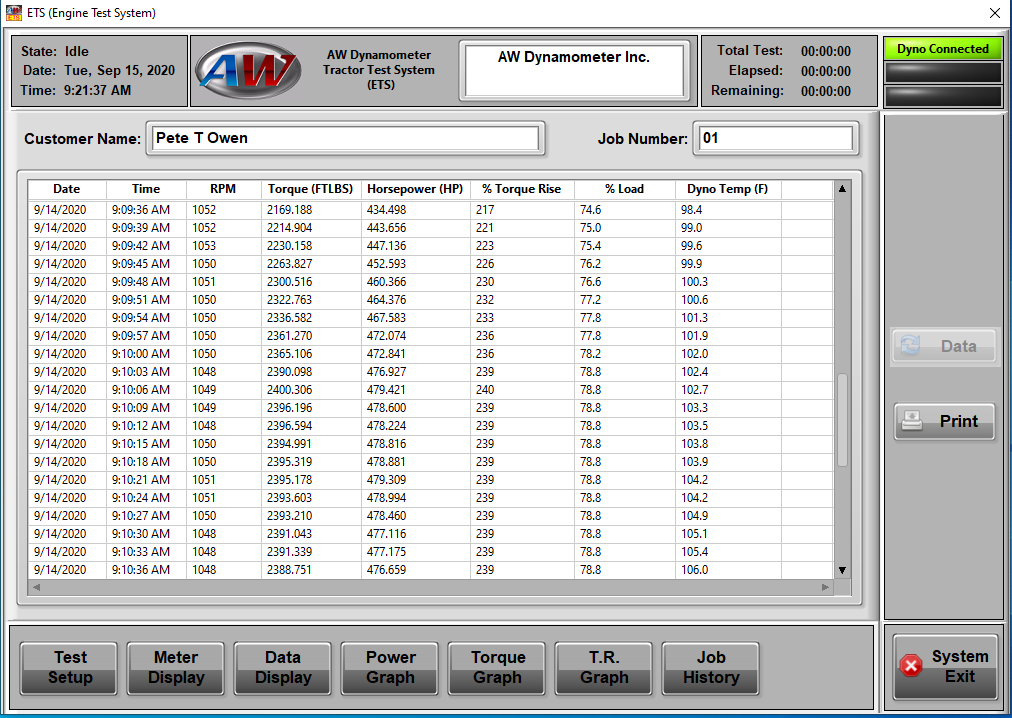

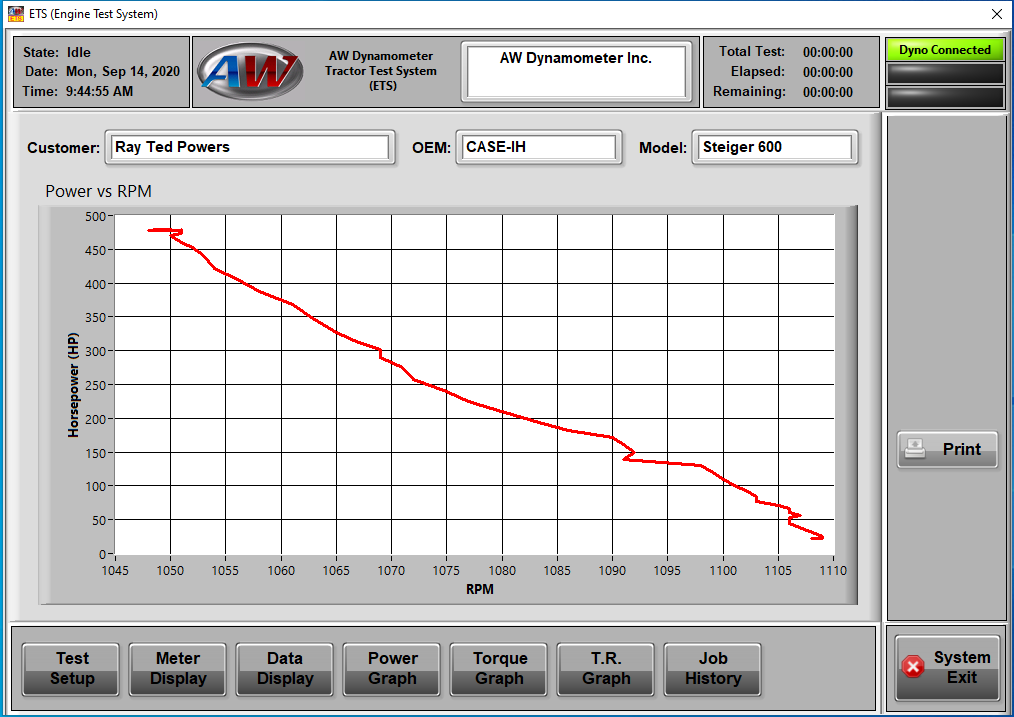

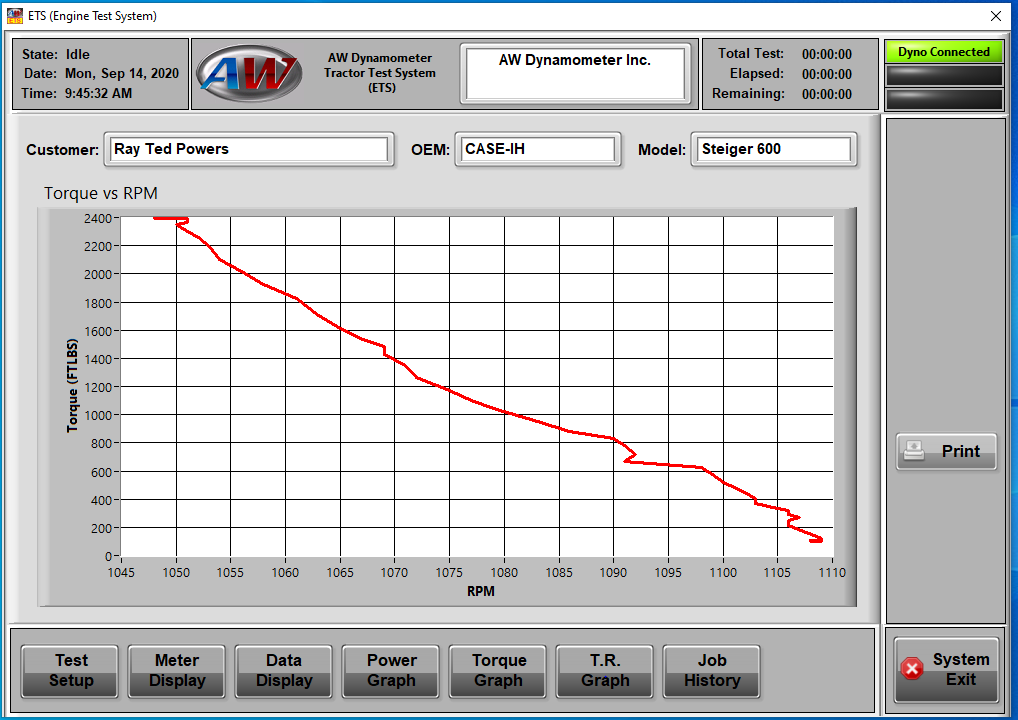

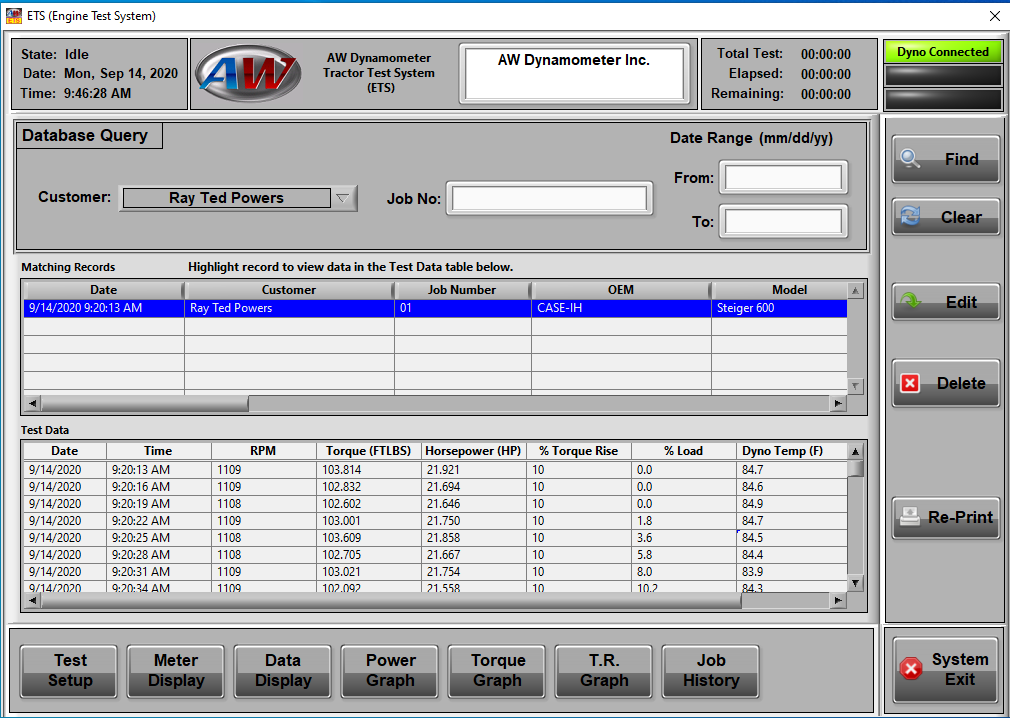

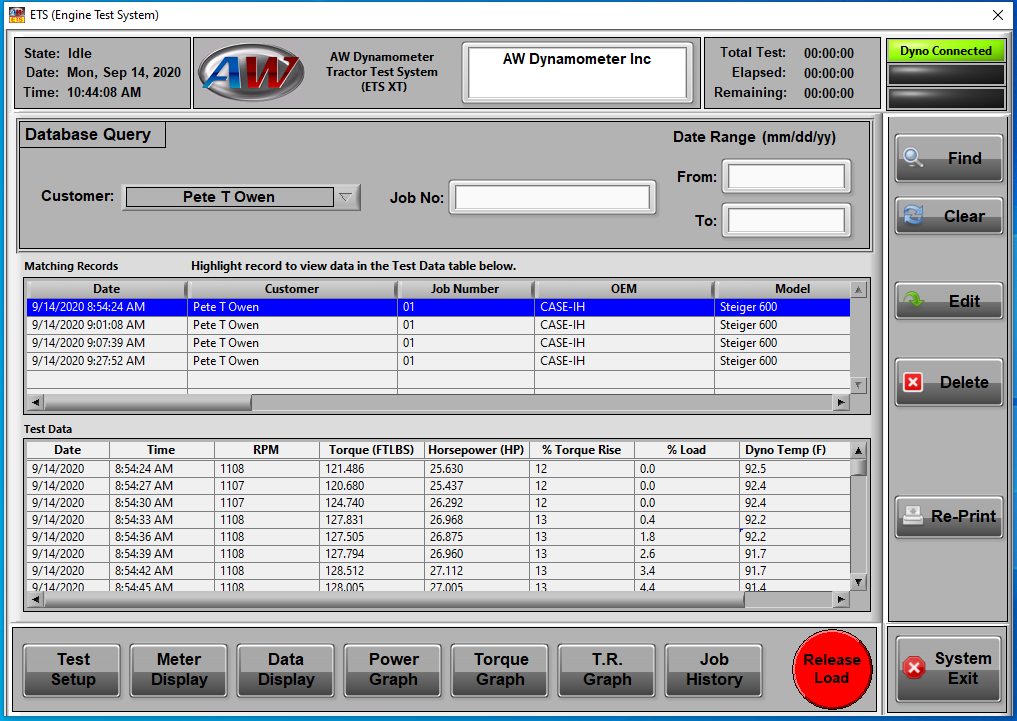

ETS Software downloads onto the end user’s laptop which in return plugs into the 2100sXT Computer via USB or Ethernet cable. It gives the technician the ability to print out detailed Test Reports to give directly to the customer during routine service inspections and or send the information to the dealer’s OEM for warranty claims. The software displays Hp, Torque, Rpm, Torque Rise, Percentage Load, and Dyno Temp in easy to read graphs and data sets. The # 1 feature is its Nebraska PTO Test Library, which contains numerous amounts of different OEM tractor test data. Tractor Specs can manually be added at any time to the user’s library. ETS also contains a job history or database in which every test performed will be collected in excel format and stored to be viewed or retrieved at a later time.

ETS XT Software

ETS XT Software

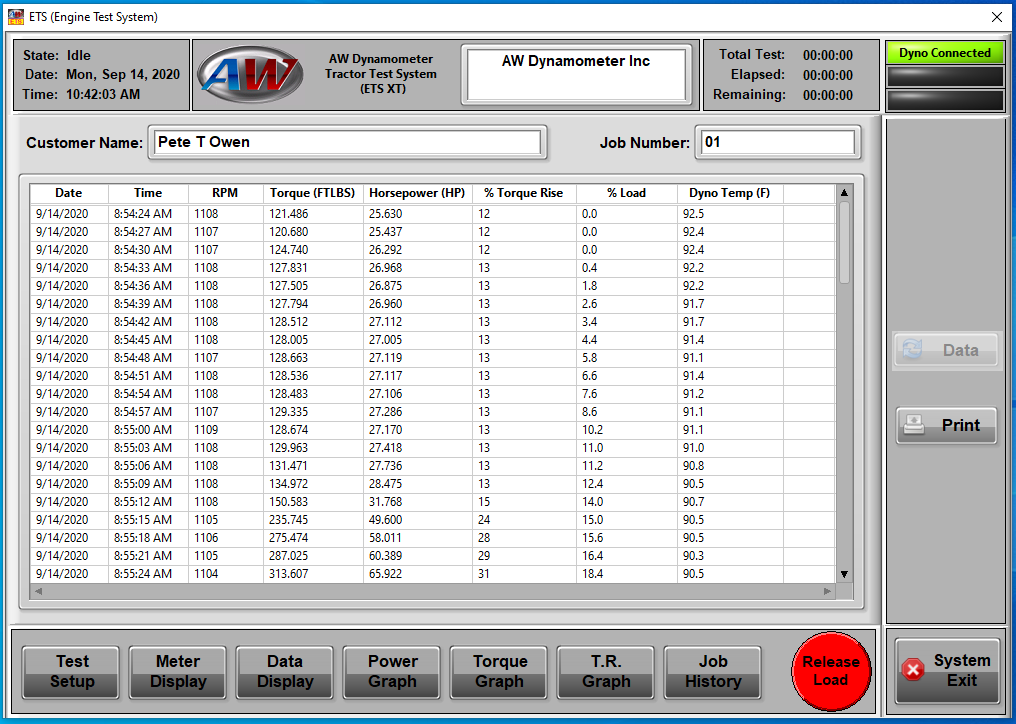

ETS-XT is a more advanced version of ETS which allows the user to control the dynamometer load via remote location such as the cab of a tractor or even the service manager’s desk. The operating screen allows you to increase or decrease the load of the dynamometer by a click of the mouse on the up and down arrow keys. The operating screen also gives you the ability to do an emergency shutdown with the E-stop button. ETS-XT Software also comes with all the features found in the ETS Software.

Critical Safeguard Protection

Critical Safeguard Protection

Temperature Watchdog Relay

This NEW High Tech feature replaces the old manual fuse (PIC ABOVE that is Circled) that would release when the dyno temp would exceed ranges of 160-180 Deg. The problem with the old manual fuse design is that it allowed for the synthetic oil inside the brake drum to begin to break down once it reached those high temperatures which then forces the end-user to flush the oil out of the drums. Temperature Watchdog is a program within the 2100sXT DynoPro Computer that releases the pressure to the brake once the dyno temperature exceeds 140 Degrees. By doing so it does not allow for the synthetic oil to break down and increases the longevity of the internal brake drum.

Water Flow Sensor

The second and most critical safeguard feature on the NEW X. Series Dynamometers is the WFS (Water Flow Sensor). This sensor is installed on the water outlet and senses how many Gpm is flowing out of the discharge. Once the flow of the water goes below the manufactured setting it sends a signal to the 2100sXT to drop the pressure to the internal brake thus saving the load unit from internal damage. The three most common reasons for lack of water to the dyno are 1. The tech forgot to turn on the water 2. The pump on the well stopped running 3. The tech backed over the outlet hose with the tractors tire.

SPECS

Max Power

900 Hp @ 1000 RPM

675 Kw @ 1000 RPM

Min Power

30 Hp @ 540 Rpm

22 Kw @ 540 Rpm

Max Torque

4725 Ft.Lbs @ 1000 Rpm

6405 Nm @ 1000 Rpm

Max Operating RPM

3000 Rpm (Reccommend High Speed Driveline for >1500 Rpm)

Standard Instrumentation

AW2100SXT DynoPro Computer System

5000 lb Strain Gauge

RPM Magnetic Tach

24V Power Supply

Electronic Load Control

Electronic Thermocouple Protection

Shear Pin Flange Protection

Standard Accessories

Rear Half PTO Shaft

Aluminum Brake Blocks

Front Caster Wheel w/ Up and Down Adjustment Bar

24 Volt Power Supply

Electrical Requirements

120 Volt 15 Amp Outlet

Weight and Dimensions

Dimensions - 83L X 53W X 66T

Weight - 2400lbs

VIDEOS

Computer & Software

Emergency Stop

Ease of Operation

AG.4X Test

TESTIMONIALS

OPTIONAL UPGRADES

Optional Accesories/Upgrades

ETS or ETS-XT

Extended Rear Half PTO Shaft (For through the wall operation)

Stationary Mount Kit

Accessible Back ½ AG Shield

Bi-Directional Valve (For testing in the opposite direction when running choppers or irrigational units)

High-Speed Driveline with AG Protection Shield (When dyno testing above 1500 Rpm’s)

High Torque Driveline Series

Electronic Water Flow Switch

Electronic Temperature Upgrade

CE Approved Plastic Guards

Electronic Fuse Assembly (Can be installed on all Nebraska Series Dynamometers)